Standards and certification

EN ISO 20471: 2013 + A1 : 2016

X = surface area class of fluorescent fabric and reflective strips (3 classes)

High-visibility warning clothing makes the wearer more visible during the day, at twilight and at night. It is legally required for anyone working on roadways and on construction sites. Even if only a limited part of the day is spent in a workplace with traffic, safety clothing must always be worn.

There are 3 classes of high visibility clothing. The more fluorescent and reflective material present in the garment, the higher the class and the visibility of the wearer*. When combing different types of classes in 1 work outfit, you can achieve a higher safety class in specific cases. Always check first which safety class is required for your specific work situation and about the resulting safety class in case of combining classes. Learn more about combining and personalising high visibility workwear.

*Note that personalising your high visibility workwear reduces the surface area of the fluorescent material. This process may jeopardise the certification of the garment. Embroidering without prior permission from a notified body is prohibited. Please contact your safety advisor for these purposes.

CLASS 3

Must be worn by everybody working on building sites, roads with a speed limit over 60 km/h, active train lines and during rescue operations.

Surface area of fluorescent material at least 0.80m²

Surface area of reflective material at least 0.20m²

CLASS 2

May be worn by people supervising the activities where class 3 warning clothing is required. Worn in good weather conditions and where visibility is adequate.

Surface area of fluorescent material at least 0.50m²

Surface area of reflective material at least 0.13m²

CLASS 1

May only be worn by people visiting a site where class 3 warning clothing is required. These visitors must be accompanied by people who work on the site. If your activities during the day vary, or if you are in any doubt, class 3 clothing is recommended.

Surface area of fluorescent material at least 0.14m²

Surface area of reflective material at least 0.10m²

All garments under this standard also meet the standards EN 340: 2003 & EN ISO 13688: 2013:

Protective clothing: general requirements. Specifies general health and ergonomic requirements as well as ageing, size designation, labelling and user instructions.

EN 14058:2017 / EN 342:2017

Protection against cool environments - EN 14058:2017

X (thermal resistance class 1 - 3)

X (air permeability class 1 - 3, optional)

X (water penetration resistance class 1 - 2, optional)

X (thermal insulation with moving dummy, optional)

X (thermal insulation with stationary dummy, optional)

Protection against cold - EN 342:2017

(humidity + wind + air temperature ≤ -5°C)

Y(B) /Y(C) /Y(R): total insulation value

(letter corresponding to undergarments used for testing)

AP (air permeability class 1-3)

WP (water resistance class 1-4, optional)

To meet the above standards, garments must be worn closed. Adjust all the functionalities on your garments to ensure that cold cannot get through (e.g. zippers, cuffs and waistband).

The thermal insulation value of the garment may decrease when wet and after cleaning procedures.

*An ‘X’ means that the garment has not been tested for that particular characteristic.

All garments under this standard also meet the standards EN 340: 2003 & EN ISO 13688: 2013:

Protective clothing: general requirements. Specifies general health and ergonomic requirements as well as ageing, size designation, labelling and user instructions.

EN 343:2019

Y (water resistance class 1-4)

Y (thermal resistance class 1-4)

R (rain tower test on the finished garment, optional)

EN343 certified safety clothing protects against precipitation (rain, snow), fog and ground humidity. The garments and seams are tested for water resistance (classes 1-4) and water vapour permeability/breathability (classes 1-4).

All garments under this standard also meet the standards EN 340: 2003 & EN ISO 13688: 2013:

Protective clothing: general requirements. Specifies general health and ergonomic requirements as well as ageing, size designation, labelling and user instructions.

EN 14404: 2004 + A1: 2010

This standard describes the test methods and requirements for knee protectors for work in the kneeling position. The DASSY knee pockets are certified in combination with DASSY® Cratos and DASSY® Fides knee pads. They offer Type 2, Level 1 protection. This means that the knee pads are suitable for flat and uneven surfaces and provide protection against the penetration of objects smaller than 1 cm.

There are four types of knee-protectors:

Type 1: “independent” knee protectors.

Type 2: pad in knee pad pocket on trousers.

Type 3: loose protectors.

Type 4: knee protectors that form part of other protection.

There are also three performance levels:

Level 0: offers no protection against penetration.

Level 1: knee protectors suitable for flat and non-flat floor surfaces and offering protection against penetration by objects < 1 cm.

Level 2: knee protectors suitable for flat and non-flat floor surfaces and offering protection against extreme conditions (e.g. scrap in mines).

All garments under this standard also meet the standards EN 340: 2003 & EN ISO 13688: 2013:

Protective clothing: general requirements. Specifies general health and ergonomic requirements as well as ageing, size designation, labelling and user instructions.

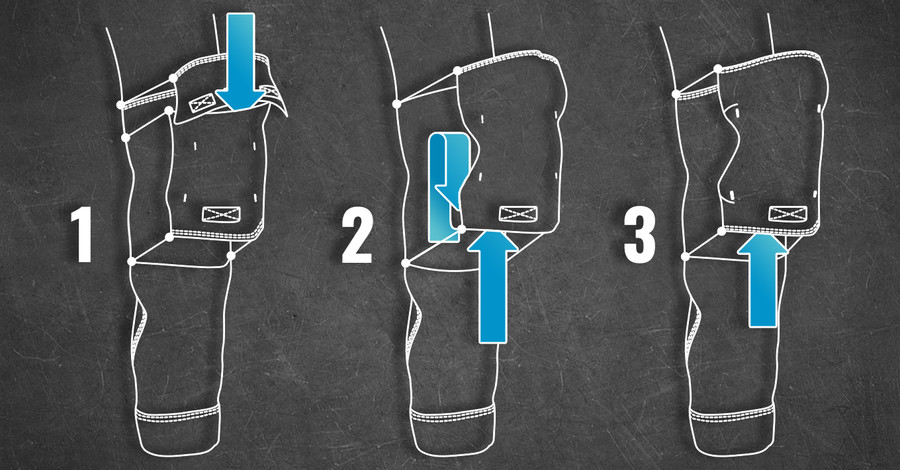

Types of knee pockets: correctly insert knee pads

In order to fully protect your knees, and because well-placed knee pads are more comfortable, it is crucial that knee pads are correctly inserted in the knee pockets of your work trousers. In the DASSY range, there are 3 different systems to position your knee pads

-

Top-loading (adjustable in height) - DASSY D-FX, DNA, CLASSIC and SAFETY

Open the top flap to insert the knee pad in the knee pocket. If you wear your trousers at a 'standard' length, keep the Velcro at the bottom of the knee pocket closed. If the knee pad is not positioned at the correct height, open the Velcro and slide the knee pad deeper down.

-

Bottom-loading (adjustable in height) - DASSY D-FX FLEX, DASSY MELBOURNE

Insert the knee pad into the knee pocket from below and place it in the pouch envelope. If you wear your trousers at a 'standard' length, keep the Velcro inside the pouch envelope closed. If the knee pad is not positioned at the correct height, open the Velcro and slide the knee pad deeper down.

-

Bottom-loading (not adjustable in height) - DASSY KNOXVILLE

Insert the knee pad into the knee pocket from below and close the Velcro

EN 13034: 2005 + A1: 2009

This standard is required for type 6 protective clothing, that provides limited protection against small spatters or fumes of liquid chemicals and is intended for use in situations where the risks are assessed as low and a full liquid permeation barrier is not necessary. This type of clothing must cover the entire upper and lower body.

All garments under this standard also meet the standards EN 340: 2003 & EN ISO 13688: 2013:

Protective clothing: general requirements. Specifies general health and ergonomic requirements as well as ageing, size designation, labelling and user instructions.

IEC 61482 - 2: 2018

An electric arc or blast as a result of a disruption (e.g. a short circuit) in an electric installation generates a sudden release of intense heat and light causing serious burns or other injuries. This standard is subdivided in different classes.

Class 1: protection against electric arc 4KA

Class 2: protection against electric arc 7KA

The clothing is tested for an arc voltage up till around 400V and for a time of 500ms.

All garments under this standard also meet the standards EN 340: 2003 & EN ISO 13688: 2013:

Protective clothing: general requirements. Specifies general health and ergonomic requirements as well as ageing, size designation, labelling and user instructions.

EN 1149 - 5: 2018

Antistatic clothing is worn to prevent sparks from electrostatic charges which can cause fire or explosion.

The standard (EN 1149) consists of various sections that specify the requirements and test methods for measuring protection against static electricity or damage from discharge. Part 5 of the standard (EN 1149-5) describes the performance requirements for antistatic clothing.

All garments under this standard also meet the standards EN 340: 2003 & EN ISO 13688: 2013:

Protective clothing: general requirements. Specifies general health and ergonomic requirements as well as ageing, size designation, labelling and user instructions.

EN 11611: 2015

This standard specifies minimum basic safety requirements and test methods for protective clothing, including head and foot safety gear, which is designed to protect the wearer’s body against spatter, short contact time with flame and radiant heat, and minimises the possibility of electrical shock (at accidental contact of +/- 100 V).

Flame spread is tested in the event of surface ignition (gives A1) and edge ignition (A2). A2 is divided into two categories, in which category 2 offers protection against more hazardous welding techniques.

A1: indicates the clothing meets the requirements for limiting flame spread in the event of surface ignition

A2: indicates the clothing meets the requirements for limiting flame spread in the edge ignition.Divided into two categories:

- Category 1 is protection against less hazardous welding techniques and situations causing low levels of spatter and radiant heat.

- Category 2 is protection against more hazardous welding techniques and situations causing higher levels of spatter and radiant heat.

All garments under this standard also meet the standards EN 340: 2003 & EN ISO 13688: 2013:

Protective clothing: general requirements. Specifies general health and ergonomic requirements as well as ageing, size designation, labelling and user instructions.

EN ISO 11612: 2015

This standard specifies performance requirements for items of clothing that are designed to protect the wearer’s body against heat and fire with the exception of the hands. The standard mentions different forms of protection, indicated by a letter and an index for performance (the higher, the better protected).

A: flame spread (2 levels)

B: iconvection heat (3 levels)

C: radiant heat (4 levels)

D: aluminium spatter (3 levels)

E: iron spatter (3 levels)

F: contact heat (3 levels)

All garments under this standard also meet the standards EN 340: 2003 & EN ISO 13688: 2013:

Protective clothing: general requirements. Specifies general health and ergonomic requirements as well as ageing, size designation, labelling and user instructions.

EN 13758-2: 2003 + A1: 2006

Clothing certified according to this standard offers protection against the sun’s rays. A UPF (Ultraviolet Protection Factor) of minimum 50 offers the highest protection by blocking more than 98% of the sun’s harmful UV radiation. The protection factor offered by clothing may be reduced with use or if stretched or wet. Only covered parts of the body are protected. Use a sunscreen with a high protection factor for uncovered parts of the body.

All garments under this standard also meet the standards EN 340: 2003 & EN ISO 13688: 2013:

Protective clothing: general requirements. Specifies general health and ergonomic requirements as well as ageing, size designation, labelling and user instructions.