Fabrics

Everything starts with the fabric. That is why strict quality requirements are set early on, at the selection of the fabrics. Subsequently, these are subject to a multitude of tests in order to achieve the best result. This resolute approach results in durable, hard-wearing and colourfast fabrics, while comfort and design also are of fundamental importance.

All raw materials meet the Oeko-tex® standards, which ensures that no harmful substances are used in our clothing.

Below a brief explanation of the various used fabrics.

Durable fabrics

| Fabric code | Fabric name | Commercial name | Composition | Weight | Properties | |

| 5005 | PA 05 | Cordura® | 100% polyamide | ± 220 g/m² |

Cordura® is a superior, durable polyamide fibre and reinforces vulnerable parts of garments. This is how we guarantee a longer service life. Cordura® retains its shape and is water- and dirt-repellent. |

|

| 5006 | PA 06 | ± 285 g/m² | ||||

| 5007 | PA 07 | Cordura® stretch | 92% polyamide - 8% elastane | ± 350 g/m² |

Cordura® stretch reinforces vulnerable parts of garments. It makes our workwear last longer. The 4-way stretch ensures total flexibility. |

|

| 5101 | PASPA 01 | Cordura® stretch for inserts | 88% polyamide - 12% elastane | ± 260 g/m² |

this Cordura® stretch is a superior, durable ripstop which we use in our inserts. The 4-way stretch inserts are applied in strategic places. This is how we guarantee ultimate freedom of movement. |

|

| 5230 | PACOSPA 30 | superstretch |

62% polyamide - 29% cotton 9% elastane |

± 210 g/m² |

Superstretch is a 4-way stretch in double weave. The cotton on the inside feels extra soft on the skin. The fabric holds its shape well thanks to the elastane, also after plenty of wash cycles. Thanks to the water repellent finish, clothing with superstretch is ideal to face rainy days. |

|

| 2061 | PESCO 61 | polyester cotton | 65% polyester - 35% cotton | ± 245 g/m² |

Polyester cotton is a durable and wear-resistant twill fabric. Nice benefit: the high colour fastness, even in case of regular washing. |

|

| 2064 | PESCO 64 | ± 300 g/m² | ||||

| 2041 | PESCO 41 | ± 250 g/m² |

Assets of PESCO 41: extra supple finish for improved wearing comfort and the light, horizontal mechanical stretch for increased freedom of movement. |

|||

| 2063 | PESCO 63 | ± 250 g/m² |

Assets of PESCO 63: the water-repellent finish and the light, horizontal mechanical stretch for increased freedom of movement. |

|||

| 3060 | COPES 60 | cotton polyester | 60% cotton - 40% polyester | ± 340 g/m² |

Polyester cotton is a durable and wear-resistant canvas fabric. The light, horizontal mechanical stretch allows for increased freedom of movement. |

|

| 1043 | CO 43 | cotton | 100% cotton | ± 320 g/m² |

Cotton is a durable and wear-resistant twill fabric. The fabric is great to wear thanks to its insulating and ventilating properties. Note that cotton is susceptible to shrinkage during the first few washes. |

|

| 3093 | COPES 93 | denim |

80% BCI-cotton - 18% polyester 2% elastane |

± 350 g/m² (10,25 oz) |

4-way stretch denim for ultimate freedom of movement. The washing ensures increased softness & flexibility. |

|

| 1094 | CO 94 | denim |

91% cotton - 8% polyester 1% elastane |

± 390 g/m² (11,5 oz) |

2-way stretch denim for extra comfort. The washing ensures increased softness & flexibility. |

|

| 2017 | PESCO 17 | beaver | 70% polyester - 30% cotton | ± 240 g/m² |

Beaver is dust- and water-repellent, making sure the fabric stays beautiful for longer. The material is quick-drying, strong and crease-resistant. |

Durable Fabrics - What does it mean to you?

Fabrics with recycled content

| Fabric code | Fabric name | Commercial name | Composition | Weight | Properties | |

| 3048 | COPES 48 | cotton - recycled polyester |

55% cotton 45% recycled polyester |

± 200 g/m² |

This antibacterial fabric for knitwear is designed with the brrr° Triple Chill Effect technology. This guarantees a cooling effect, easy moisturewicking and quick drying. In addition, the cotton-recycled polyester is treated for an anti-pilling finish. Bye-bye fluff balls! Finally, this fabric is PFC-free, with no intentional use of PFCs. |

|

| 4109 | PESPA 09 |

recycled polyester polyamide |

76% recycled polyester 24% polyamide |

± 200 g/m² |

This antibacterial fabric for knitwear features a subtle geometric design. Recycled polyester/polyamide easily wicks away moisture and is PFC-free, with no intentional use of PFCs. |

|

| 2087 | PESCO 87 | recycled polyester - cotton |

64% recycled polyester 36% cotton |

± 310 g/m² |

This knitwear fabric is brushed on the inside. Wonderfully soft, warm and comfortable! In addition, the recycled polyester-cotton is treated for an anti-pilling finish. Bye-bye fluff balls! Finally, this fabric is PFC-free, with no intentional use of PFCs. |

|

| 2038 | PESCO 38 |

recycled polyester cotton |

51% recycled polyester 6% polyester - 34% BCI cotton 9% elastomultiester |

± 250 g/m² |

Recycled polyester-cotton is a woven, durable and wear-resistant fabric with ripstop for extra strength. The 2-way stretch allows for sufficient comfort and ease of movement. This fabric is PFC-free, with no intentional use of PFCs. |

|

| 5102 | PASPA 02 |

Cordura® stretch for knee pads |

90% PA66 Cordura® (virgin) 10% spandex |

± 350 g/m² |

Woven fabric with superior durability thanks to Cordura® yarns. In 4-way stretch for ultimate freedom of movement. With ripstop to reinforce the knee pockets and ensure wear resistance. This fabric is PFC-free, with no intentional use of PFCs. |

|

| 2114 | PESSPA 14 |

recycled polyester elastane |

66% recycled polyester 26% polyester - 8% elastane |

± 280 g/m² |

Diamond-textured knit. Brushed on the inside, making it wonderfully soft, warm and comfortable! In 4-way stretch for ultimate freedom of movement. Treated for a PFC-free, durable, water-repellent finish and the fabric is also PFC-free, with no intentional use of PFCs. |

|

| 4083 | PES 83 | recycled polyester | 100% recycled polyester | ± 90 g/m² |

Recycled polyester with twill weave is a very lightweight, windproof fabric with mechanical stretch. Features wear-resistant ripstop. Treated for a PFC-free, durable, water-repellent finish and the fabric is also PFC-free, with no intentional use of PFCs. |

|

| 4081 | PES 81 | recycled polyester | 100% recycled polyester | ± 170 g/m² |

Recycled polyester is a lightweight, windproof and waterproof fabric with mechanical stretch. Has a breathable PU membrane. Treated for a PFC-free, durable, water-repellent finish and the fabric is also PFC-free, with no intentional use of PFCs. |

|

| 4084 | PES 84 | recycled polyester | 100% recycled polyester | ± 160 g/m² |

Recycled polyester is a lightweight, windproof and waterproof fabric with mechanical stretch. With wear-resistant ripstop and a breathable PU membrane. Treated for a PFC-free, durable, water-repellent finish and the fabric is also PFCfree, with no intentional use of PFCs. |

|

| 5114 | PASPA 14 | polyamide - elastane |

50% recycled polyester 44% polyamide - 6% elastane |

± 280 g/m² |

A double-layered diamond-textured softshell in 4-way stretch for increased ease of movement. In fleece for extra comfort and warmth on the inside. Treated for a PFC-free, durable, waterrepellent finish and the fabric is also PFC-free, with no intentional use of PFCs. |

|

| 5309 | PAPES 09 |

polyamide recycled polyester |

60% recycled polyamide 40% recycled polyester |

± 163 g/m² |

Melange fabric with two-tone effect. Creates a modern look. With antibacterial finish and PFC free, with no intentional use. |

Waterperformance fabrics

| Fabric code | Fabric name | Commercial name | Composition | Weight | Properties | |

| 4021 | PES 21 | three-layered softshell | 100% polyester | ± 280 g/m² |

A three-layered softshell consisting of a woven outer layer, a breathing membrane and inner layer fleece lining. The fabric is waterproof thanks to its water-repellent treatment, windproof and ventilates well when perspiring. Besides, the fabric is slightly elastic for increased freedom of movement. |

|

| 4074 | PES 74 |

three-layered HiVis softshell |

100% polyester | ± 280 g/m² |

A three-layered softshell consisting of a woven HiVis outer layer, a breathing membrane and inner layer fleece lining The fabric is waterproof thanks to its water-repellent treatment, windproof and ventilates well when perspiring Besides, the fabric is slightly elastic for increased freedom of movement. |

|

| 4070 | PES 70 | coated polyester | 100% polyester - PU-coating | ± 200 g/m² |

Coated polyester is windproof and waterproof thanks to its water-repellent treatment. Breathable polyurethane (PU) coating allows transpiration moisture to evaporate. |

|

| 4080 | PES 80 | laminated polyester | 100% polyester - TPU-lamination | ± 200 g/m² |

Laminated polyester in Oxford weave is windproof and waterproof thanks to its water-repellent treatment. The breathable membrane with thermoplastic polyurethane (TPU) lamination allows transpiration moisture to evaporate. |

|

| 4090 | PES 90 | laminated polyester | 100% polyester - TPU-lamination | ± 240 g/m² |

Laminated polyester in canvas weave is windproof and waterproof thanks to its waterrepellent treatment. The breathable membrane with thermoplastic polyurethane lamination allows transpiration moisture to evaporate. |

|

| 5194 | PASPA 94 |

laminated polyamide with elastane |

88% polyamide - 12% elastane DWR-lamination |

± 200 g/m² |

Laminated polyester with elastane is windproof and waterproof thanks to its water-repellent treatment. The breathable membrane allows transpiration moisture to evaporate. Additional benefit: 4-way stretch for ultimate freedom of movement. |

Waterproofness, breathability and cold protection - What does it mean to you?

Knitwear

| Fabric code | Fabric name | Commercial name | Composition | Weight | Properties | |

| 1006 | CO 06 | cotton single jersey | 100% cotton | ± 180 g/m² |

Cotton is a natural, strong and durable fibre. The fabric breathes and is very light, which makes cotton nice to wear. Note that cotton is susceptible to shrinkage during the first few washes. |

|

| 1104 | COSPA 04 |

cotton single jersey with elastane |

92% cotton - 8% elastane | ± 190 g/m² |

Single jersey cotton with elastane, pre-shrunk fabric which is also extra flexible. The fabric consists of combed cotton, making the yarns soft and supple to touch. |

|

| 1105 | COSPA 05 | ± 220 g/m² | ||||

| 1146 | COSPA 46 |

cotton piqué with elastane |

97% cotton - 3% elastane | ± 220 g/m² |

Cotton piqué with elastane is a breathable, durable and easy-care fabric. Plus: the fabric is less susceptible to shrinkage during the first washes. |

|

| 3016 | COPES 16 | blend single jersey | 50% cotton - 50% polyester | ± 185 g/m² |

Blend single jersey and blend polo piqué are very hard-wearing and high colourfast fabrics. fabrics are suited for industrial washing at 75° according to PRO label. During the production,both fabrics were pre-shrunk, and therefore resistant to shrinking. |

|

| 3056 | COPES 56 | blend polo piqué | ± 215 g/m² | |||

| 3080 | COPES 80 | sweatshirt fabric | 80% cotton - 20% polyester | ± 290 g/m² | Sweatshirt fabric combed inside for improved comfort and warmth. | |

| 3086 | COPES 86 | 65% cotton - 35% polyester | ± 305 g/m² |

The fabric has a double-sided even appearance due to Interlock and feels smooth on the skin. |

||

| 3090 | COPES 90 | 80% cotton - 20% polyester | ± 340 g/m² | Sweatshirt fabric combed inside for improved comfort and warmth. | ||

| 4016 | PES 16 | micro polar fleece | 100% polyester | ± 260 g/m² |

Micro polar fleece is combed inside and outside for improved comfort and warmth. The fabric also underwent an anti-pilling treatment, so say goodbye to fluffs. |

|

| 4038 | PES 38 | tricot fleece | 100% polyester | ± 290 g/m² |

Tricot fleece is combed in one colour inside and outside for improved comfort and warmth. The outer fabric is a melange tricot for a modern look. |

|

| 4004 | PES 04 | polyester bird eye | 100% polyester | ± 140 g/m² |

Polyester bird eye and polyester piqué are quick drying, inherently antibacterial fabrics. The fabrics offer UV protection (UPF 50+) against the radiation of the sun. |

|

| 4044 | PES 44 | polyester piqué | 215 g/m² | |||

| 9201 | WOPA 01 | thermal merino | 75% merino wool - 25% polyamide | ± 180 g/m² |

Thermal merino has a woven-in design (jacquard) and fits closely to the body thanks to 4-way stretch. The fabric consists of antibacterial merino, ideal for avoiding odours. Furthermore, the fabric is extra warm, moisturewicking, thermoregulating and quick-drying. |

|

| 9101 | PPPAEA 01 | thermal active |

70% polypropylene Siltex 22% polyamide - 8% elastane |

± 145 g/m² |

Thermal active has a woven-in design (jacquard) and fits closely to the body thanks to 4-way stretch. The fabric consists of antibacterial PROLEN® Siltex, ideal for avoiding odours. Furthermore, the fabric is moisture-wicking, thermoregulating and quick-drying. |

Safety fabrics

| Fabric code | Fabric name | Commercial name | Composition | Weight | Properties | |

| 2070 | PESCO 70 |

HiVis polyester - cotton |

69% polyester - 31% cotton | ± 250 g/m² |

HiVis polyester cotton is a durable and wearresistant twill fabric. Clothing made of HiVis polyester cotton can take a beating, as the fabric is dirt-repellent treated. Extra advantage with PESCO 70: the fabric is very light. |

|

| 2074 | PESCO 74 | 60% polyester - 40% cotton | ± 290 g/m² | |||

| 2176 | PESCOSPA 76 |

HiVis polyester - cotton stretch |

70% polyester - 28% cotton 2% elastane |

± 270 g/m² |

HiVis polyester cotton is a durable and wearresistant twill fabric. Clothing made of HiVis polyester cotton can take a beating, as the fabric is dirt-repellent treated. The 2-way stretch allows for extra comfort. |

|

| 2084 | PESCO 84 | HiVis sweater fabric | 65% polyester - 35% cotton | ± 280 g/m² | The sweatshirt fabric is combed inside for improved comfort and warmth. | |

| 4021 | PES 12 | HiVis polar fleece | 100% polyester | ± 280 g/m² |

The high visibility polar fleece is combed inside and outside for improved comfort and warmth. The fabric also underwent an anti-pilling treatment, so say goodbye to fluffs. |

|

| 4006 | PES 06 | HiVis polyester bird eye | 100% polyester | ± 150 g/m² |

HiVis polyester bird eye is a quick-drying, inherently antibacterial fabric. The fabric offers UV protection (UPF 50+) against the radiation of the sun. |

|

| 3054 | COPES 54 |

HiVis cotton - polyester piqué |

55% cotton - 45% polyester | ± 170 g/m² |

High visibility cotton polyester is a quick-drying, inherently antibacterial fabric. The fabric offers UV protection (UPF 50+) against the radiation of the sun. |

|

| 1073 | CO 73 | flame-retardant cotton | 100% cotton | ± 340 g/m² |

Flame-retardant cotton is a fabric of European origin with flame-retardant finish. Safety first. |

|

| 3075 | COPES 75 |

Multinorm cotton - polyester |

75% cotton - 24% polyester 1% Nega-Stat® |

± 290 g/m² |

(HiVis) Multinorm cotton polyester is a fabric of European origin with flame-retardant finish. Moreover, it is inherently antistatic: the flameretardant properties are naturally present in hte fibres. Safety at its very best. |

|

| 3077 | COPES 77 |

HiVis-Multinorm cotton - polyester |

50% cotton - 49% polyester 1% Nega-Stat® |

± 330 g/m² | ||

| 2135 | PESSPA 35 | fleece with elastane | 94% polyester - 6% elastane | ± 260 g/m² |

Fleece with elastane is extra flexible and combed on the inside for extra comfort and warmth. The fabric also underwent an anti-pilling treatment, so say goodbye to fluffs. |

|

| 4074 | PES 74 |

three-layered HiVis softshell |

100% polyester | ± 280 g/m² |

A three-layered softshell consisting of a woven HiVis outer layer, a breathing membrane and inner layer fleece lining The fabric is waterproof thanks to its water-repellent treatment, windproof and ventilates well when perspiring. Besides, the fabric is slightly elastic for increased freedom of movement. |

|

| 4070 | PES 70 | coated polyester | 100% polyester - PU-coating | ± 200 g/m² |

Coated polyester is windproof and waterproof thanks to its water-repellent treatment. Breathable polyurethane (PU) coating allows transpiration moisture to evaporate. |

Certified fabrics - What does it mean to you?

Waterproofness, breathability and cold protection - What does it mean to you?

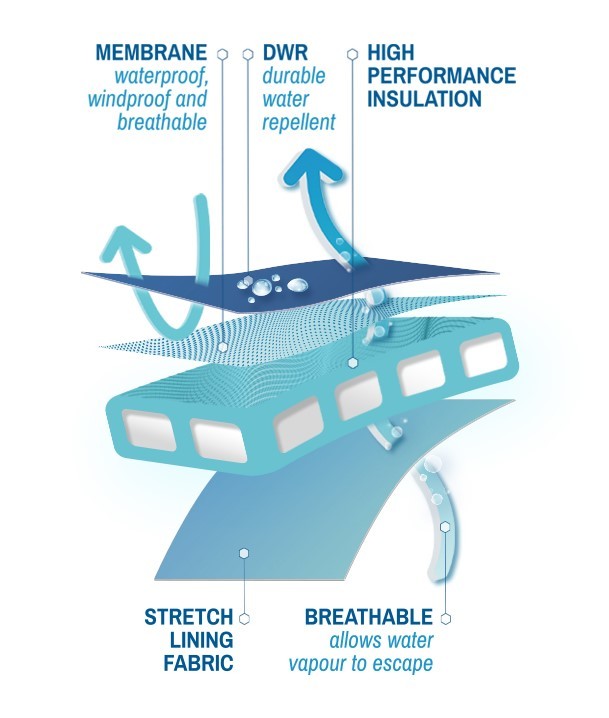

Breathable

The breathability of the fabric ensures that transpiration moisture can escape quickly. This enables you to stay dry while at work. The permeability of a fabric is measured on the basis of the speed with which water vapour can escape. This is expressed in “MVP”, or “Moisture Vapour Permeability”. The higher the MVP value, the stronger the breathability of the fabric.

Waterproof

A waterproof fabric ensures that rain and snow cannot penetrate for a long time, enabling you to stay dry and continue to work even in bad weather. A fabric’s waterproofness is determined by measuring the quantity of water – the so-called “water column” – a fabric can resist before moisture starts to penetrate. This is expressed in “WR”, or “Water Resistance”. The higher the result, the longer you can continue to work in bad weather without experiencing any discomfort.

With regards to the waterproofness of a piece of clothing, 100% watertight taped seams are another important ally. Finally, applying a finish on the outer layer of fabric also adds an extra layer of protection by making moisture bead up and roll off.

Example: the image displays the different fabric layers of the DASSY® Nordix stretch winter jacket. The DWR finish (Durable Water Repellent) makes water droplets bead up and roll off, while the wind- and waterproof membrane effectively keeps out rain and wind. And since the membrane is also breathable, water vapour can easily escape from the inside.

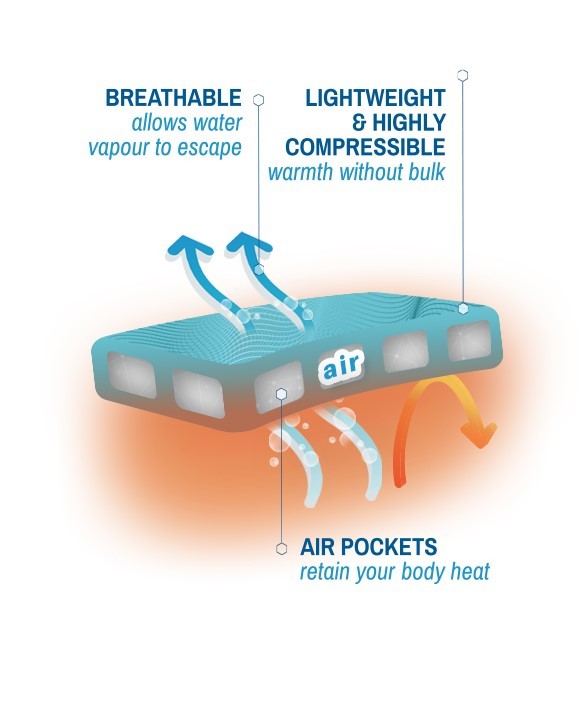

Cold protection

A good thermal insulator traps your body’s radiated warmth. Since air excels as an insulator, paddings consist of countless small air pockets that effectively retain body heat. That way, you can continue working comfortably even in colder weather.

Example: the image displays the high quality insulation of the DASSY® Nordix stretch winter jacket. The high performance DuPont™ Sorona® micro fibres create small air pockets for the best warmth-insulation.

Moreover, this padding is also light, breathable, soft, quick drying and it is made of 37% renewable plant-based materials. And since the DuPont™Sorona® fibre is also highly compressible, the DASSY® Nordix keeps you nice and warm, without looking puffy.

Durable Fabrics - What does it mean to you?

Tensile properties and tear resistance

Durable fabrics do not tear easily. We perform thorough tests on our fabrics to ensure appropriate tensile and tear resistance. This is for example done by means of a tear test, in which a small incision is made in both directions of the fabric, after which we measure the strength required to tear the fabric further. Similar tests are carried out to determine the tensile resistance of the fabric. In this case, we measure the strength required to tear the fabric over a certain width without making an incision in advance. In both cases the strength of the fabric is in proportion to the strength required to tear the fabric.

Abrasion resistance

Another way to define the durability of a fabric is to define the fabric’s resistance to abrasion. This is measured by subjecting the fabric to a rotating, concentric rub under a certain amount of pressure. The test result is expressed in the number of cycles (rubs or revolutions) the device has made until visible abrasion appears. The higher this number, the more durable the fabric and the longer your piece of clothing will last.

Apart from these tests, all fabrics are also thoroughly tested for seam slippage resistance, anti-pilling properties and colour fastness combined with appropriate washing tests. We test all fabrics in our own labs and also have them tested by independent and internationally recognised testing institutes. This enables us to guarantee you the best results.